Our Services

Engineering services

Steel fabricating and installations

Steel has been one of the most desired materials for a while now, and it has different type of appliances. The impressive toughness and other factors are the reason why steel components are used in pretty much anything, from transportation appliances to structures or entire buildings.

Steel fabrication is a process that can be performed using multiple different methods or approaches. Such as cutting, shearing, bending, welding and machining. Any kind of steel items fabricating and repairing works can be done in our place.

We are mainly work with coconut industry related machineries, Gantry, Food related mixing machines, Hoist, SS wash basin, Coconut storage racks, Coconut store bins etc

Factory designing

(coconut oil and milk plants)

The future of factory design brings with its great challenges, especially considering the market growth and progress development associated with it. Increasing market dynamics and ever-growing customer requirements, are just some of the challenges facing on designing the factories.

Production planning and factory design is helpful to avoid misunderstandings. These two different tasks naturally result in different requirements, methods and processes. The main goals of factory design are usually similar for all types of project. In addition to high productivity and efficiency, there is also a strong focus on safe working conditions and good space utilization.

We are mainly designing virgin coconut plants (V.C.O.) and coconut milk plants only. Designing process can be done on site visit and customized the floor plan on the customer requirement.

Re-engineering

Factory re-engineering is the process of redesigning and optimizing the manufacturing processes in a factory to improve the efficiency, quality, and competitiveness of the products. It involves applying new technologies, methods, and principles to the entire production system, from raw materials to finished goods.

Production factory re-engineering can have a positive impact on the performance, productivity, and profitability of a manufacturing company, as well as on the customer satisfaction and loyalty. However, it also requires a significant investment, planning, and commitment from the management and employees.

Machine design and fabrication works

The meaning of machine design and fabrication works is the process of creating and building machines, parts, and structures from raw materials using various engineering principles, tools, and techniques. It involves both the conceptual design of the machine elements and the physical fabrication of the components using cutting, bending, welding, machining, and assembling methods.

We are fabricating coconut related machineries and products. Also, we are done any machine modifications and upgrades as per the customer requirements.

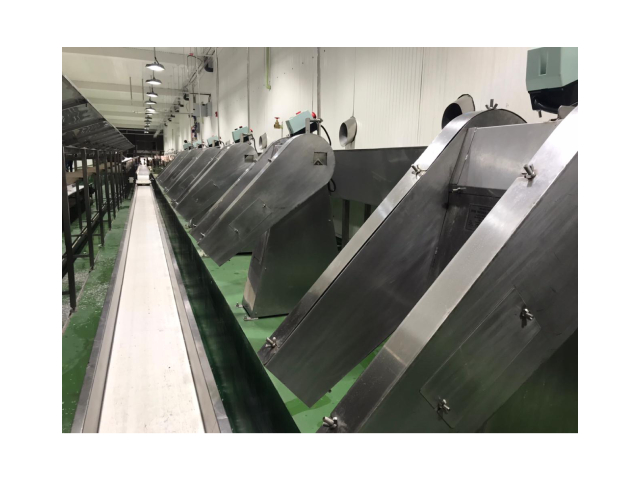

Coconut milk plants wet section design, fabrication and installation

BME works offers, coconut milk plants wet section designing, fabrication of machineries and products, installation works of these items are done under one roof. All required machineries and steel products to wet section of the coconut milk plants can be supplied and installed. We have 20 years of experience in coconut related works.

All kinds of mechanical engineering works & maintaining

We are performed mechanical engineering works, maintaining of the machineries and fabrication works, such as design, develop, build, test, and maintain the machines and equipment that are used to produce machinery items or structural works using processes like cutting, bending, and assembling in our workshop.

All kind of steel piping works

BME Works fabricate and installed coconut milk collecting and distributing piping line of milk plants, coconut oil collecting and distributing piping line of oil plants, high pressure steam lines, gas piping lines by using stainless steel pipes. We are done lot of piping projects around coconut milk and oil plants.

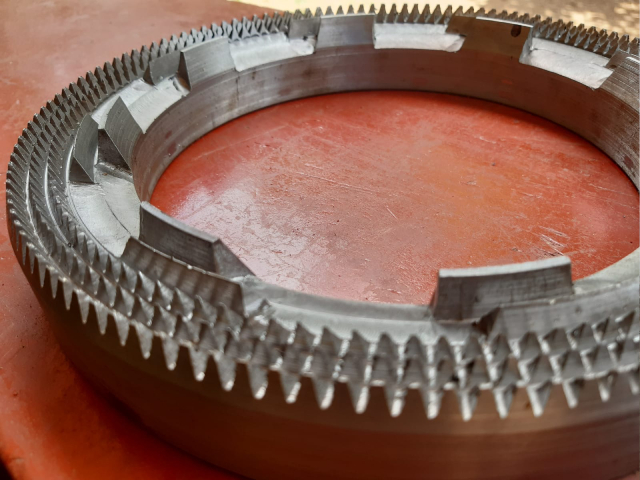

DC cutter rim cut and recut

Desiccated coconut is a form of coconut that is dried and grated from the white flesh of fresh coconuts. It has a dry and flaky texture and a mild and sweet coconut flavor.

Desiccated coconut is different from shredded coconut, which is larger and moister, and coconut flour, which is finer and lower in fat. Desiccated coconut can be found in various forms, such as fine, medium, or coarse flakes, chips, or granules.

Desiccated coconut making machine called DC cutter. It has two cutter rims for grinding the white flesh of the fresh coconuts. We are making new rims for any rim sizes. Also, we are re-cutting the wearable old rims and it can be used again.

Our Machineries

Our Machineries and Products

Coconut oil extraction machine

This Model is the small type of screw oil press machine provided by BME Works Pvt Ltd. It can process various oilseeds and oil crops, like soybeans, peanut/groundnut, palm kernel, copra, etc. The small size, cheap price and superior functions make it the most cost-effective oil pressing equipment for farmers, mini or small size oil factory.

- Material: Mild Steel and Stainless steel

- Capacity: 35kg-50kg per hour

- Motor: 15hp / 3 Phase

- Dimensions: 5ft x 4ft x 4ft

- Function—extract coconut oil from copra pieces

De-Shelling machine

This model of deshelling machine has an overall capacity of deshelling 400-500 nuts per every hour. The capacity and the speed range are between 7-8 nuts every minute. It has a safety cover and an easy-adjust drive unit. You can make other adjustments too as per requirement.

- Dimensions: Height – 1220mm Length – 475mm Width – 555mm

- Power Supply- 400V/3Ph/50Hz

- Number of Operators- 1

- Capacity – 5000 Nuts/10 hour

- Motor – 0.5HP Gear motor (Gear Ratio 1:30)

- Motor brand name – LGLEM Three phase Asynchronous motor (Germen Technology)

- Manufacturing Materials – Mild steel and High-Speed Steel

- Specifications – On/Off switch with DOL & Emergency Stop button included

- DOL brand name – Schneider

- Function – Removing the coconut shell from the nut

Paring machine (Single head)

This coconut paring machine scalps off the soft and brownish skin, or testa, of deshelled coconut kernel (in pieces) via a rotating trimming cutter. An operator is required to feed the pieces of deshelled coconut kernel into the machine during the paring process

- Dimensions: Height – 1220mm Length – 475mm Width – 555mm

- Capacity – 5000 Nuts/10 hour (Depends on skill of the operator)

- No of operators – 1 Operators

- Motor – 1HP Gear motor (rpm 2830,2 pole synchronize)

- Motor Brand – LGLEM

- DOL brand – Shnider

- Manufacturing Materials – Stainless Steel

- Specifications – On/Off switch with DOL & Emergency Stop button included

- Function—peeling the brown skin of coconut nut

Paring machine (Double head)

This coconut paring machine scalps off the soft and brownish skin, or testa, of deshelled coconut kernel (in pieces) via a rotating trimming cutter. An operator is required to feed the pieces of deshelled coconut kernel into the machine during the paring process. In this type of double head paring machine, two operators can be work on same time in two sides.

- Dimensions: Height – 1220mm Length – 475mm Width – 555mm

- Capacity – 5000 Nuts/10-hour one side (Depends on skill of the operator)

- No of operators – 2 Operators

- Motor – 1HP Gear motor (rpm 2830,2 pole synchronize)

- Motor Brand – LGLEM

- DOL brand – Shnider

- Manufacturing Materials – Stainless Steel

- Specifications – On/Off switch with DOL & Emergency Stop button included

- Function—peeling the brown skin of coconut nuts

Philippine cutter machine

The machine has an enormous capacity of desiccating about 1200 kgs to 1300kg of moist coconut meat per hour. The operation is easy, and you can adjust it as per the size requirement. There is an automatic feed presser machine with a feed screw.

- Material: Stainless Steel/Semi SS/ full MS available

- Capacity: 5000nuts per hour (1200kg-1300kg)

- Motor: 20 hp/ 3 phase

- Feeder motor: 2hp gear motor (1:30 gear ratio)

- Dimensions: 7ft x 2ft x 4ft

- Functions—make coconut chip, flakes, desiccated (fine, medium, super fine)

Pre cutter

This machine is effective in cutting coconuts into two halves. The accessibility is 3–4-piece coconut. The machine operates under high-grade technology and demands little maintenance. The cutting knife is made from stainless steel, and there is a discharge hopper as well.

- Material: Stainless steel

- Capacity: 5000nuts per hour

- Motor: 2hp / 1 phase

- Dimensions: 2ft x 2ft

- Gear Set: (1:30 gear ratio)

- Kernel cutting size (3”-4”)

- SS-304 construction.

- Easy maintenance.

- Easy to clean.

- Dewatering and water collection chamber.

- No blockage.

- Three phase electric motor drive.

Vibrating Cooling table

This machinery has efficient technology, which helps in the mass production of desiccated coconut. It can use it to dry coconut powder, both high fat and low-fat desiccated powder, chips, flakes etc.

- Material: Stainless Steel

- Function: dryer is used to dry coconut powder, both high fat and low-fat desiccated powder. Its main function is to remove moisture content from coconut powder to increase the shelf life without disrupting the nutritional values of the coconut powder.

Storage tanks

We are designing and fabricating storage tanks by fully Stainless Steel (304) Construction. It has screw conveyor system to tale out the storage. This storage tanks used to store white kernel of the coconut for other preparations.

- Material: Mild steel / Stainless Steel

Shell crushing machine

Shell crusher is a machine can be used to crush the deshelled coconut shells. Shell pieces auto feeding system are available, through the screw conveyors after the deshelling process.

- Material: MS

- Capacity: depend on customer requirement

- Function: crushing coconut shells from deshelling machine

Screw Conveyors

Screw conveyor is a kind of conveying machine that uses motor to drive spiral rotation to move materials to realize transportation. Screw conveyor is suitable for horizontal conveying, inclined conveying and vertical conveying of particles or powdered materials. It is a widely used conveying equipment coconut related industry. We are manufacturing and designing all kind of screw conveyors. All the products can be customized as per the customer requirement.

- Material: Mild steel / Stainless Steel

Counting Conveyor

- Material: MS/ SS

- Capacity: 7500kg per hour

- Motor:

- Dimensions:

Belt Conveyor

We are designing and manufacturing many types of counting conveyors as per the customer requirement.

- Material: Mild steel / Stainless Steel

Milk Expeller machine

Coconut Milk Extraction machine is used to extract milk and low-fat desiccated coconut powder. The material used is complete Stainless Steel 304 Food grade.We BME Works introduce ourselves as a well-known manufacturer and supplier of superior quality Coconut Milk Extractor. The amount of Coconut milk produced depends on the pressure applied at the time of pressing grated coconut. The higher the pressure, the more Coconut milk is obtained. Some commercial mechanical pressing tools that available in the market are not efficient due to the working steps too much and take long time per cycle of work. But our Coconut Milk Squeezer reduces the cycle time.

Material: Stainless Steel (304) Construction

Capacity: 500L per hour

Washing Drums

Rotary washer has a rotating drum with two stage washing system. High pressure waster is sprayed on the products while rotating inside the drum. In this system there is no blockage and uniform cleaning of all coconuts is ensured. Also, Coconut meat into the washing machine, first the roller soaked in the water tank start rolling and washing coconut. Wish the help of baffle in the rotating drum and drum rolling, the coconut will be pushed forward to the discharge direction. There are many sprayers above the discharge port. And they will spay raw material again to achieve the purpose of the secondary cleaning. This is widely used in coconut processing line. This machine can also be used in washing of any type of vegetables, fruits, raisins etc.

- SS-304 construction.

- Easy maintenance.

- High pressure water sprayer washing system.

- Two stage washing system.

- Inspection window on top side.

- Three phase electric geared motor drive.

- Provision for hot water sprayer.

- Capacity: 5000- 10000 per hour

Devil cutter

- Material: MS/ SS

- Capacity: 7500kg per hour

- Motor:

- Dimensions: